HYDROGEN

For effective climate protection, it is essential to switch energy production to almost exclusively wind and solar power plants. However, a consistent supply cannot be guaranteed due to seasonal and weather-related fluctuations. On good days, more energy is generated than is needed, while on bad days with little wind and sun, there is a risk of shortages. The production of hydrogen, which makes surplus renewable energy storable and usable in industrial processes, could compensate for this.

Until now, hydrogen has been obtained almost exclusively from fossil fuels, releasing CO2 and thus contradicting climate protection goals. Yet the technological alternative has long been available. Electrolysis splits water into hydrogen and oxygen, so the raw material could not be any cheaper.

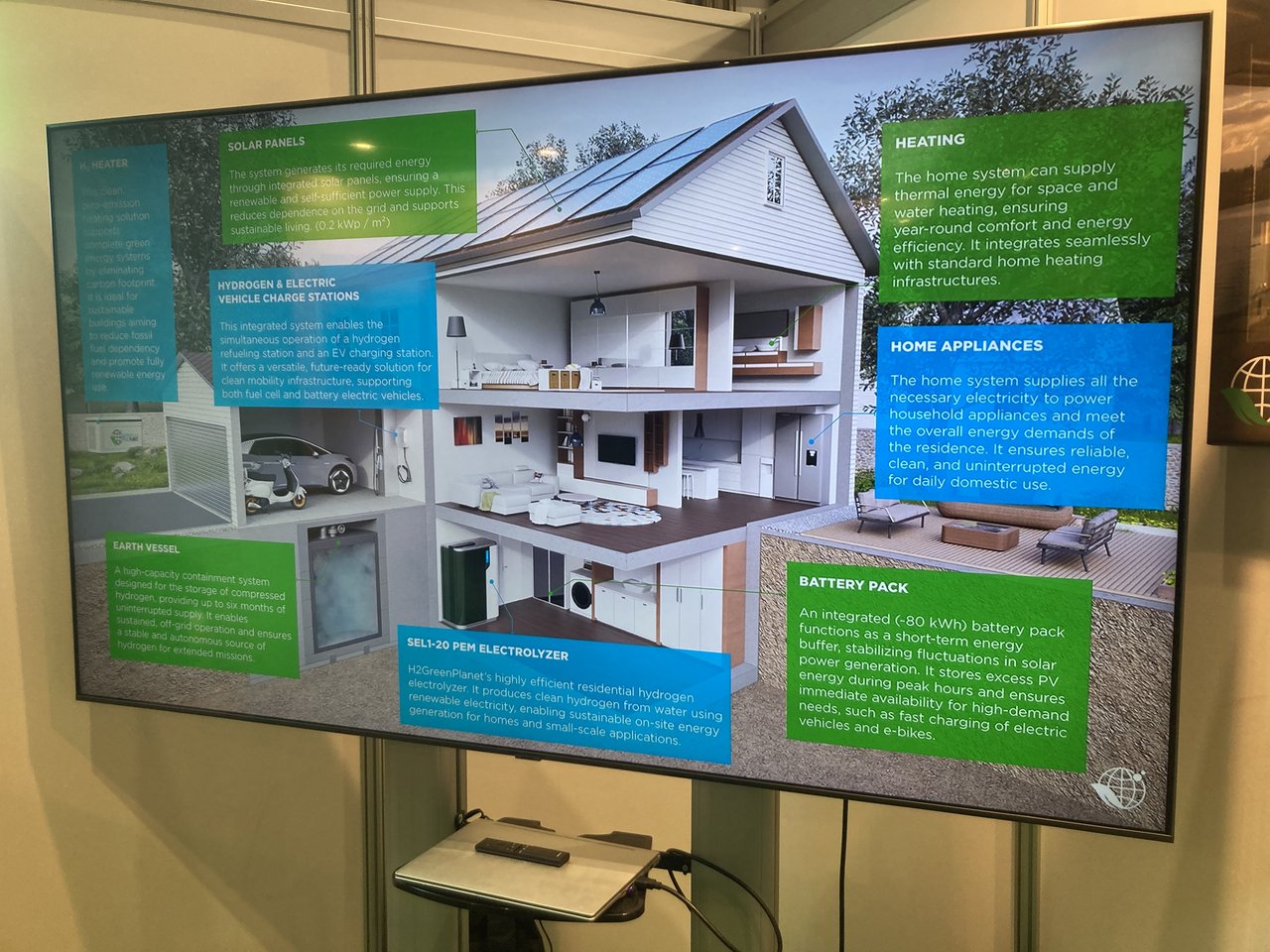

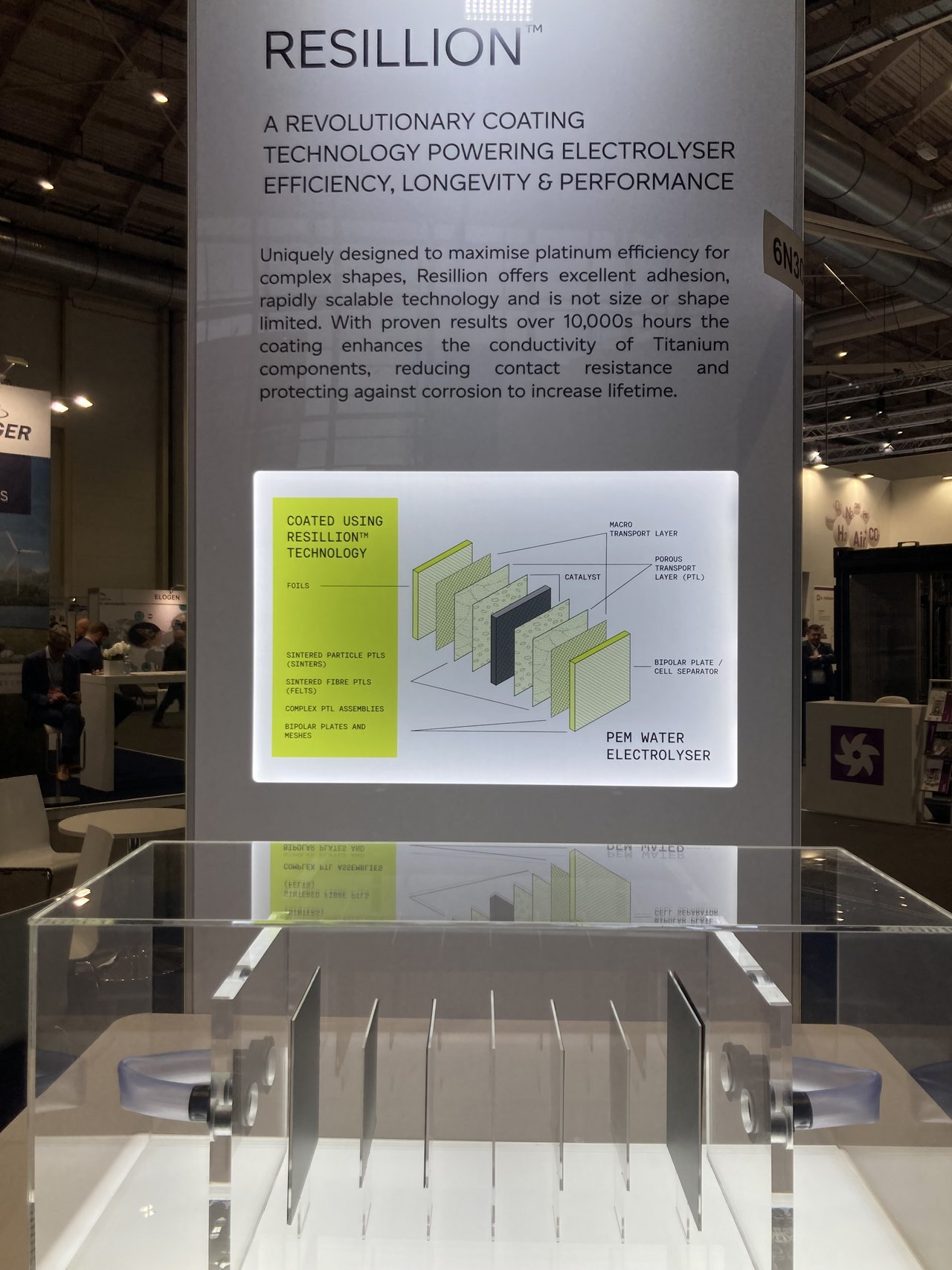

The device that makes this process possible is called an electrolyser. The core element of an electrolyser is the membrane electrode assembly (MEA) surrounded by water. When an electrical voltage is applied, the water is split. The MEA can be compared to the chip in a computer: it makes all the difference.

The electrolyser increases the cost factor many times over. One of the main raw materials used in its construction is iridium. Iridium is one of the rarest metals in existence, considerably rarer than gold or platinum. Only between eight and nine tonnes are mined annually, most of it in South Africa. Global demand is rising steadily, and with current technology, demand would be three times higher than supply. It is therefore very expensive and hardly scalable.

elementarhy GmbH has developed an MEA that combines several advantages over other models. Particularly significant is the demand for iridium, which is reduced by 95% with elementarhy's technology. This is made possible by a thin-film process that reduces overall material consumption, including for platinum, which is also processed. Initial test runs have shown cost savings of up to 50%.

The new technology is also considerably more environmentally friendly. Per- and polyfluoroalkyl substances (PFAS), also known as forever chemicals, have been used for catalyst coating up to now. As the name suggests, they are extremely persistent and therefore pollute the environment. In the USA and Europe, bans are at least under discussion and, in some cases, have already been decided. elementarhy has developed a PFAS-free catalyst coating and can therefore offer MEAs without these chemicals much more easily.