BAMBOO CLAY WOOD HOUSES

HEALTHY LIVING

With natural, low-emission building materials and home furnishings

SOLID WOOD HOUSES

Wood has a natural healing effect on us humans. Numerous studies and tests have shown that spending time in the forest and in a solid wood environment lowers the pulse rate, has an anti-inflammatory effect and ensures better sleep.

So-called healing forests are springing up like mushrooms in Germany. They are designed to help people regain their health, find peace and relaxation.

Wood is sensual. It feels warm, smells good and creates a sense of well-being in a wooden house. The overall living climate of a house is made up of many individual factors. Whether we feel cosy and comfortable in a house depends on all of these. No sweating in summer, no freezing in winter: This is what ideal thermal comfort feels like. A perfect feel-good climate. The diffusion-open construction of solid wood walls makes it easy to keep the indoor air temperature and humidity at the right level. Both factors influence the room climate.

Just like the air movement. Outdoors, a little breeze can refresh the air pleasantly.

Indoors, however, the situation is different. Some draughts in the room quickly blow away the cosy feeling. The special construction of timber houses means that they fulfil the requirements for air and wind tightness in accordance with DIN 4108. Additional measures are only required for buildings with higher requirements, such as passive and efficiency houses.

Odour sensitivity

If odours occur when entering rooms that can be traced back to material leaks and cause discomfort, then processed solvents in adhesives and paints may be responsible.

In the case of indoor air quality in solid wood houses, this question does not even arise. Everyone is also well protected from unpleasant sound or disturbing noise. These are all factors that influence cosiness. Just like a suitable room layout, good lighting, pleasant colours and the choice of interior materials.

It is therefore important to ensure that no glue or other chemicals are used during the entire manufacturing process. This means that no unpleasant or unhealthy odours or vapours are inhaled. Provided, of course, that outgassing ceilings, roof trusses, paints, furniture and plastics are also avoided.

Solid wood houses are ideal for allergy sufferers

as natural wooden surfaces have an antibacterial effect. This prevents germs from growing on the surface. Wooden surfaces are also antistatic and raise less dust. All you will feel and smell is wood.

The ideal humidity in a house is between 50 and 60 per cent. Wood is as clay a naturally moisture regulator. It absorbs moisture and releases it again if it is too dry. Such regulated indoor humidity has a positive effect on the respiratory tract, eyes and skin.

The solid wood wall also offers you advantages in terms of radiation protection: Together with aluminium grooved pins, the solid wood construction absorbs high-frequency radiation from outside (e.g. mobile phone transmitters). In order to achieve continuous protection, additional measures are recommended for all non-wall components such as roof structures, ceilings or windows.

There is a natural magnetic field on earth. It is regarded as an important organising and orientation factor for all life. Building biology research shows that the human organism reacts negatively to technically or artificially induced DC magnetic fields.

It is therefore important not to install any magnetising steel components that disturb the earth's natural magnetic field. Aluminium grooved pins are not magnetic.

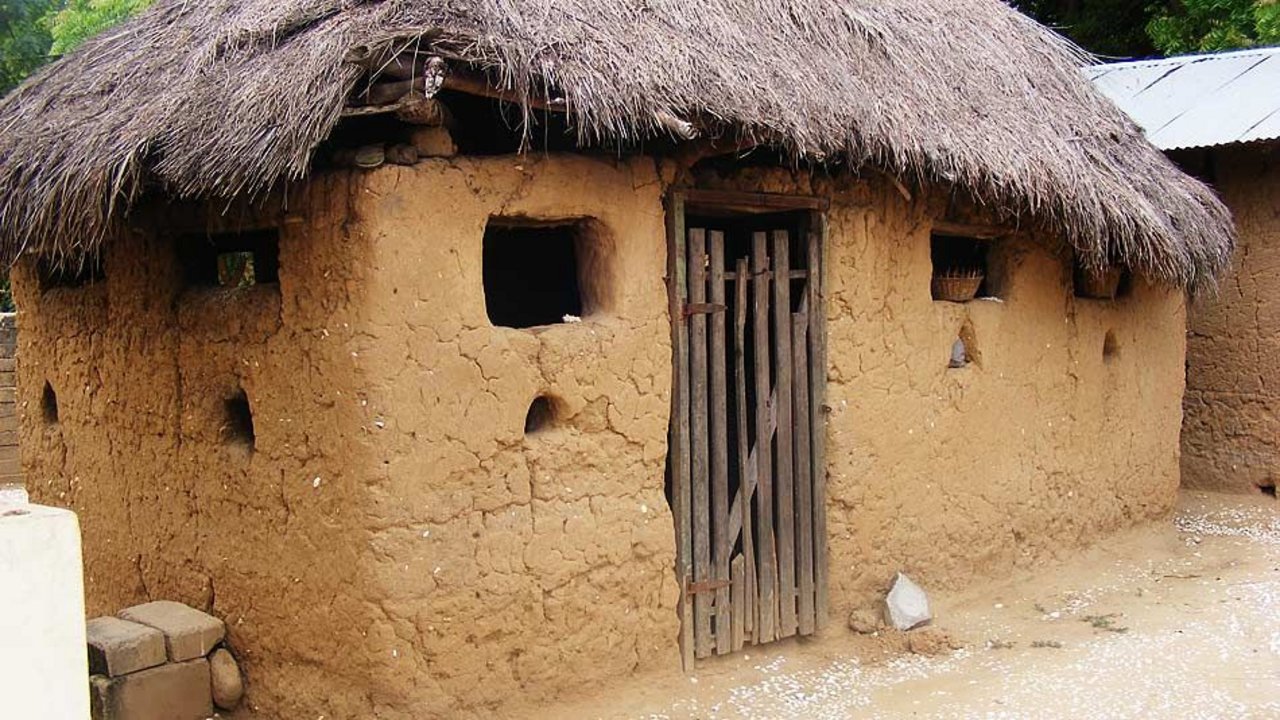

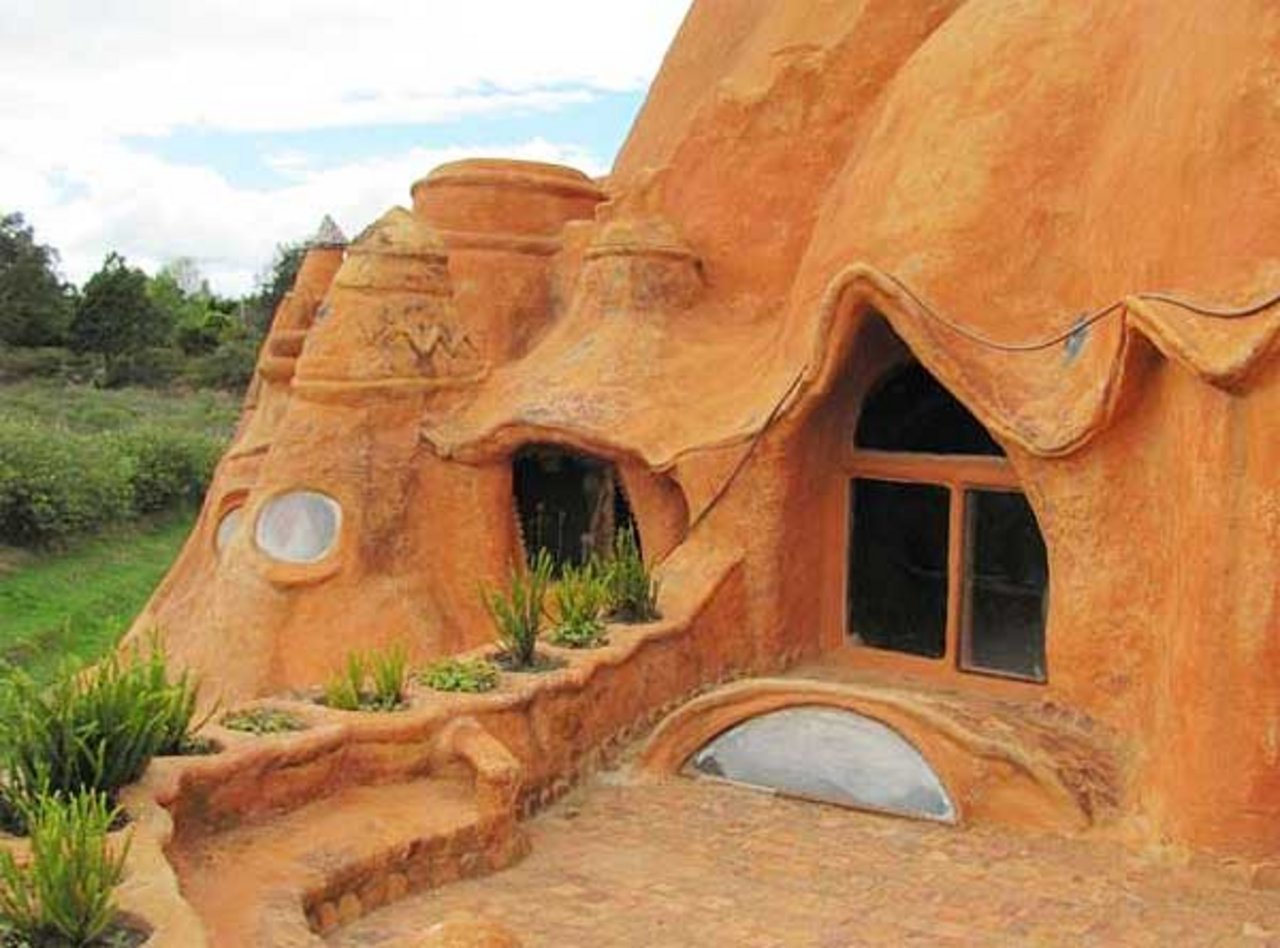

CLAY HOUSES

Traditional clay construction with bricks is labour-intensive and time-consuming.

EARTH CONCRETE

Use excavated material containing clay and turn it into an alternative concrete without adding cement. Earthcrete can be poured when fresh, hardens quickly and is suitable for use in floors and non-load-bearing walls.

The processing is similar to that of conventional concrete and utilises a similar infrastructure. This technology gives clay construction almost all the advantages of cement, but is around 2.5 times cheaper and 20 times more environmentally friendly.

ETH spin-off Oxara. A technical achievement of ETH Zurich

Gnanli Landrou from Togo, doctoral thesis under Prof Guillaume Habert

Challenges of the global construction industry

Energy and CO2-intensive cement production, the dwindling raw materials sand and gravel and the high cost of concrete, which is simply too expensive in many countries.

Sandcrete blocks, in particular, have since become widespread in Ghana and other West African countries. These building blocks, made of a lot of sand, a little water and a little cement, are moulded into cuboids using sheet metal or wooden formwork and then harden.

Depending on the production method and compaction, they achieve compressive strength values of between one and around 3.5 N/mm².

In terms of quality, the bricks are often not of sufficient quality and tend to break and erode due to the high sand content. The advantage of these bricks is their comparatively favourable price.

The problem with the widespread use of this building product is the high consumption of cement, one of the largest CO2 emitters in the world, and also the enormous amount of sand used.

The sand required is often extracted unregulated from riverbeds or illegally from beaches, leading to environmental problems and land loss, which particularly affects coastal areas.

Development of sustainable bricks with laterite

In an endeavour to avoid the consumption of sand and imported cement and at the same time offer an affordable, practicable building material, a brick was developed in 2015 that completely dispenses with sand and saves 60% of the cement.

Laterite earth is found in large parts of West Africa and is available in abundance.

These sustainable bricks consist mainly of laterite, a fully weathered and characteristically red earth. During the manufacturing process, they are pressed under pressure to form a moulded brick that is mechanically interlocked with adjacent bricks. This means that mortar does not need to be used between the stone layers during the construction process (so-called dry masonry).

Laterite earth is a widespread surface product in West Africa and is a by-product of (open-cast) mining, for example, or can be extracted during earthworks or levelling on the site to be built on and processed into bricks.

Due to the interlocking of bricks, the flat dimensions and the absence of mortar, they can also be laid by people who have no specialist knowledge in the construction sector. Training or instruction by a specialist on the building site is sufficient.

BAMBOO HOUSES

BAMBOO - a very special grass

Bamboo is a grass and therefore not a true woody plant. It is increasingly coming into focus worldwide as a sustainable raw material and is also becoming more and more important as a strategic element in the global development agenda. Over 30 million hectares are spread across the world. And Bamboo is not only one of the fastest growing renewable raw materials on earth; it is also one of the most versatile materials in the world.

The natural building material combines the compressive strength of concrete with the tensile strength of steel. In contrast to these conventional building materials, however, bamboo has a decisive advantage:

Instead of releasing carbon dioxide during the manufacturing process, the renewable raw material binds the greenhouse gas as it grows. The plant regenerates quickly after harvesting and shoots up almost a metre in height in just one week. Thanks to its predominantly hollow structure, bamboo is extremely light. As a natural raw material, the bamboo stalks are irregularly shaped and not the same thickness everywhere. In addition, the segments (internodes) vary in length. This poses particular challenges for processing.

Bamboo grows out of a network of roots, the rhizomes. The tips of the rhizomes bend upwards out of the root network and form the new culms. This overlapping of root systems over several hectares provides good protection against erosion. In addition, it acts as a moisture reservoir and can be used as a root clarifier for settlements and farmsteads. Due to its high growth rate, bamboo is suitable for the reforestation of rainforest areas in developing countries. Its ability to bind large quantities of CO2 as it grows also speaks in favour of its ecological benefits.

Each shoot that sprouts from the ground already contains all the nodes (nodes), internodes (chambers) and diaphragms (partitions) that are compressed telescopically. Bamboo culms are usually hollow and have a circular cross-section. The diameter and wall thickness decrease with increasing height.

After the third year of life, the culms become woody and silicified, only then are the culms fully suitable for load-bearing parts. The outermost layer of the culm has a high silica content, which is why it is very resistant to external attacks. The surface of the bamboo cane is very smooth and fine and therefore does not need to be reworked. The colour varies from yellowish to brown, black, dotted, spotted, matt and shiny.

- There are an estimated 1.200 species and 90 genera of bamboo worldwide

- The bamboo plant is a sustainable and rapidly renewable raw material

- Bamboo has very good material properties and can be used in many different ways.

- Bamboo stores a lot of carbon during its rapid growth. Bamboo is therefore one of the plants that absorbs the most CO2 during its lifetime. It also releases around 35% more oxygen than trees of the same size.

- The bamboo plant continuously forms new culms via its root system. Large quantities can be harvested every year without the plant dying and jeopardising the population. This means that future generations will never run out of bamboo.

- Bamboo prevents soil erosion.

- Bamboo offers a constantly growing variety of possible uses and provides sustainable alternatives to the use of increasingly scarce resources such as wood, metal or oil.

- Bamboo grows in some of the poorest regions of the world. As a strategic element in the global development agenda, the cultivation, processing and utilisation of bamboo can create work and income in particularly structurally weak regions.

- Bamboo is an extremely sustainable and durable building material if it is preserved using environmentally friendly salt infusions. Fences and furnitures, kitchen utensils can be produced

- Bamboo can be used as music instruments

- Rhizomes and shoots are used for food. Leaves for herbal tea.

- Bamboo processing waste can be converted into high quality charcoal. For purifying water, removing odor, keeping food fresh, maintaining soil alkanity. Being use as additive in food and cosmetics. For treatment of allergies and sore throat, as skin and hair conditioner.

The bamboo plant produces a substance (bamboo kun) that protects it from pests and fungal attack. This makes bamboo naturally anti-bacterial, anti-microbial and hypo-allergenic. Bamboo products are therefore also very suitable for allergy sufferers.

When bamboo is harvested, the plant continues to sprout underground root systems (known as rhizomes) so that the entire population is not jeopardised by its harvest. Bamboo is very sustainable to grow as it requires neither fertilisers nor pesticides and draws its water from nature. Many bamboo varieties are even resistant to drought. The bamboo plant is very resilient, can grow on supposedly infertile and steep slopes and is even planted in erosion-prone areas due to its branched root systems for soil stability.

It provides countless opportunities to create employment and income for people whose lives have previously been characterised by poverty and disadvantage.

IMPORTED BUILDING MATERIALS

Nowadays, a large proportion of building materials are imported to Ghana. This also includes cement and cement clinker, which are exclusively imported to Ghana, often from China.

The biggest CO2 emitter and driver of climate change is concrete. Ground lime (calcium carbonate - CaCO2) and clay (silicate-rich earth). Heated in a rotary kiln up to 1,450° C, whereby lime oxidises to quicklime (calcium oxide CaO). carbon dioxide is produced as a waste product. Worldwide, 10 billion tonnes of concrete are now produced every year.

After the heyday of West African tropical architecture in the 1950s and 60s, whose architects aimed to use modern building materials sustainably and adapted to the climate, traditional materials and construction methods as well as ideas of tropical architecture have been increasingly displaced since the 1970s.

This displacement was primarily due to economic reasons and a shift towards privatisation policies. The increasing popularity of Western-style architecture, which is considered modern and prestigious in Ghana, intensified the move away from the more favourable construction methods.