NATURAL BUILDING MATERIAL

Traditionally, there were many different construction methods in the region of today's Ghana. Depending on the type of vegetation and climate, which varies greatly in Ghana from north to south and east to west, various local building materials were used.

These materials ranged from clay to wood, bamboo, straw, tree parts and palm leaves to natural stones.

BAMBOO - a very special grass

BAMBOO - a very special grass

Bamboo is increasingly coming into focus worldwide as a sustainable raw material and is also becoming more and more important as a strategic element in the global development agenda.

Bamboo is not only one of the fastest growing renewable raw materials on earth; it is also one of the most versatile materials in the world.

Bamboo is a grass and therefore not a true woody plant.

The natural building material combines the compressive strength of concrete with the tensile strength of steel. In contrast to these conventional building materials, however, bamboo has a decisive advantage:

Instead of releasing carbon dioxide during the manufacturing process, the renewable raw material binds the greenhouse gas as it grows.

The plant regenerates quickly after harvesting and shoots up almost a metre in height in just one week. Thanks to its predominantly hollow structure, bamboo is extremely light. As a natural raw material, the bamboo stalks are irregularly shaped and not the same thickness everywhere. In addition, the segments (internodes) vary in length. This poses particular challenges for processing.

Bamboo grows out of a network of roots, the rhizomes. The tips of the rhizomes bend upwards out of the root network and form the new culms. This overlapping of root systems over several hectares provides good protection against erosion. In addition, it acts as a moisture reservoir and can be used as a root clarifier for settlements and farmsteads. Due to its high growth rate, bamboo is suitable for the reforestation of rainforest areas in developing countries. Its ability to bind large quantities of CO2 as it grows also speaks in favour of its ecological benefits.

Each shoot that sprouts from the ground already contains all the nodes (nodes), internodes (chambers) and diaphragms (partitions) that are compressed telescopically. Bamboo culms are usually hollow and have a circular cross-section. The diameter and wall thickness decrease with increasing height.

After the third year of life, the culms become woody and silicified, only then are the culms fully suitable for load-bearing parts. The outermost layer of the culm has a high silica content, which is why it is very resistant to external attacks. The surface of the bamboo cane is very smooth and fine and therefore does not need to be reworked. The colour varies from yellowish to brown, black, dotted, spotted, matt and shiny.

The bamboo plant is a sustainable and rapidly renewable raw material

Bamboo has very good material properties and can be used in many different ways.

Bamboo stores a lot of carbon during its rapid growth. Bamboo is therefore one of the plants that absorbs the most CO2 during its lifetime. It also releases around 35% more oxygen than trees of the same size.

The bamboo plant continuously forms new culms via its root system. Large quantities can be harvested every year without the plant dying and jeopardising the population. This means that future generations will never run out of bamboo.

Bamboo prevents soil erosion.

Bamboo offers a constantly growing variety of possible uses and provides sustainable alternatives to the use of increasingly scarce resources such as wood, metal or oil.

Bamboo is an extremely sustainable and durable building material if it is preserved using environmentally friendly salt infusions.

Bamboo grows in some of the poorest regions of the world. As a strategic element in the global development agenda, the cultivation, processing and utilisation of bamboo can create work and income in particularly structurally weak regions.

The bamboo plant produces a substance (bamboo kun) that protects it from pests and fungal attack. This makes bamboo naturally anti-bacterial, anti-microbial and hypo-allergenic. Bamboo products are therefore also very suitable for allergy sufferers.

When bamboo is harvested, the plant continues to sprout underground root systems (known as rhizomes) so that the entire population is not jeopardised by its harvest. Bamboo is very sustainable to grow as it requires neither fertilisers nor pesticides and draws its water from nature. Many bamboo varieties are even resistant to drought. The bamboo plant is very resilient, can grow on supposedly infertile and steep slopes and is even planted in erosion-prone areas due to its branched root systems for soil stability.

It provides countless opportunities to create employment and income for people whose lives have previously been characterised by poverty and disadvantage.

WOOD

African wood species

From pink-grey to copper-coloured to dark brown - African wood species not only have a wide range of different colours to offer.

The areas of application are also wide-ranging. Some of the African wood species, such as Moabi and Denya wood, are often used for interior and exterior construction. Tali wood is used for bridge construction, wharfs or truss construction, as it can withstand very heavy loads. African woods, such as Iroko wood, are also suitable for stairs, furniture, parquet flooring and boat building.

The special thing about wood species from Africa is their resistance to pest and fungal infestation. Often no chemical wood protection against fungi and insects is required.

Versatile, resistant and universally applicable - Read more about the individual African wood species here.

Properties of African wood species

| Wood Species | Areas | Weight (kg/m³)* | Durability |

| Abachi | West- & Centralafrica | 400 | 5 (very low) |

| Bilinga | Trop. West- & Centralafrica | 800 | 1 (very good) |

| Bongossi | Ivory Coast, Gabon, Ghana, Equatorial Africa, Cameroon, Congo, Liberia, Nigeria, Sierra Leone, Zaire, Central African Republic | 1.100 | 2 (good) |

| Ceiba | - | 330 | 5 (very low) |

| Dabema | West- & Eastafrica | 700 | 3 (moderate) |

| Denya | West- & Centralafrica | 1.000 | 1 (very good) |

| Iroko | Tropical Africa | 690 | 1-2 (good up to very good) |

| Moabi | Westafrica | 830 | - |

| Okoume | Equatorial Guinea, Gabun, VR Congo | 440 | 4 (moderate) |

| Tali | Ivory Coast, Ghana, Cameroon, Gabon, PR Congo, Mozambique, Zambia, Zaire | 970 | - |

* Weight at 12-15% moisture

CEDRELA

is a Genus with several species from the family of the Mahagony Plants, Meliaceae.

Soap trees (Sapindales) | |

Mahagony Crop (Meliaceae) | |

Westindian Cedrele |

West Indian Cedrela

These are evergreen or deciduous deciduous trees with pinnate leaves, which are native to the tropical and subtropical region of Ghana and from southern Mexico to northern Argentina.

Cedro wood is characterised by its light texture, strength similar to pine wood and good workability. It is weatherproof and resistant to fungal attack and insects. Typical uses include boat building, furniture, windows and veneer production.

Cedro wood comes from the tree species Cedrela - Western Red Cedar from the giant cedar tree, a type of cypress, and real cedar wood is very rare and hardly common. It is particularly misleading that the cedrela is actually a deciduous tree, but has been given the name of a conifer (namely cedar).

Cedro is neither a true cedar nor should it be confused with the American red cedar. Both are different tree species.

DIN abbreviation

The DIN designation for Cedro is CEXX

Grain

The pores are clearly visible, coarse and often dark in colour. They can vary in size and frequency in different areas of the wood. A clear veining can be recognised, but the wood rays are barely visible. So-called "blood veins" are typical of cedrela.

Colour

The heartwood is initially pale yellowish or slightly reddish-brown in colour. It darkens when exposed to light. Very dark qualities come either from areas far to the south or from high altitudes.

Characteristics

Cedro wood is light and has strengths that are roughly equivalent to pine wood. It is easy to work with and is also similar to pine. Resin may come out in some places.

Shrinkage and drying

Drying takes only a short time, there is hardly any tendency to warp or crack. Cedro wood shrinks only moderately.

Resistance

Cedro is quite weather-resistant and also well resistant to fungal attack, as well as quite well resistant to insects

Use

Cedro is versatile and can also be whitewashed like oak. The darker (somewhat harder) wood is mainly used for stressed structures. Sports boats and their interiors, profiles, frames and panelling as well as windows can be made from cedro. It is also suitable for veneer production and modelling.

Prices in Germany are around EUR 2,400-2,800 per cubic metre.

CLAY

Clay is not only beneficial to health as a building material and has the ability to absorb pollutants from water and the air.

WATER CONTAINERS

Traditionally used water storage vessels filter bacteria, viruses and parasites from collected water. Due to the membrane-like filter function, waste water can be used as drinking water. Clay also has cooling properties.

CLAY PLASTER

Clay plasters regulate indoor humidity, insulate sound, store heat and absorb odours.

Use in hospital rooms

Clay plasters in patient rooms make an important contribution to a healthy indoor climate. They balance out "moisture peaks" that can occur in the rooms for a short time when showering.

No general statement can be made about the cost difference between clay and concrete ceilings, as many factors influence the construction costs. In the case of the Swiss Triemli Hospital, the clay ceiling - with inserted, thin, water-bearing pipes - is more cost-effective than technical solutions with comparable functionalities.

Clay that is no longer required can be returned to the soil as it contains no harmful substances and is water-soluble.

LATERITE SOIL

Building blocks, made of a lot of sand, some water and a little cement, are formed into a cuboid shape with the help of sheet metal or wooden formwork and then harden.

Depending on the method of production and compaction, they achieve compressive strength values between one and about 3.5 N/mm².

Qualitatively, the bricks are often not of sufficient quality and tend to break and erode due to the high sand content. The advantage of these bricks is again the comparatively low price.

Problematic about the proliferation of this building product is the high consumption of cement, one of the largest CO2 emitters in the world, and also the enormous sand consumption.

The sand required is often extracted unregulated from riverbeds or illegally from beaches, leading to environmental problems and land loss there, which particularly affects coastal villages.

The coast of the project region of NaBiG e. V. and Sustainable Building Foundation in the central region of Ghana is also strongly affected by this and directly affects our organisation members.

Development of sustainable bricks

In an effort to avoid the resource consumption of sand and imported cement while offering an affordable, viable building material, we developed a masonry brick from 2015 that completely eliminates sand and saves 60% of cement.

Laterite soil is found in large parts of West Africa and is abundant.

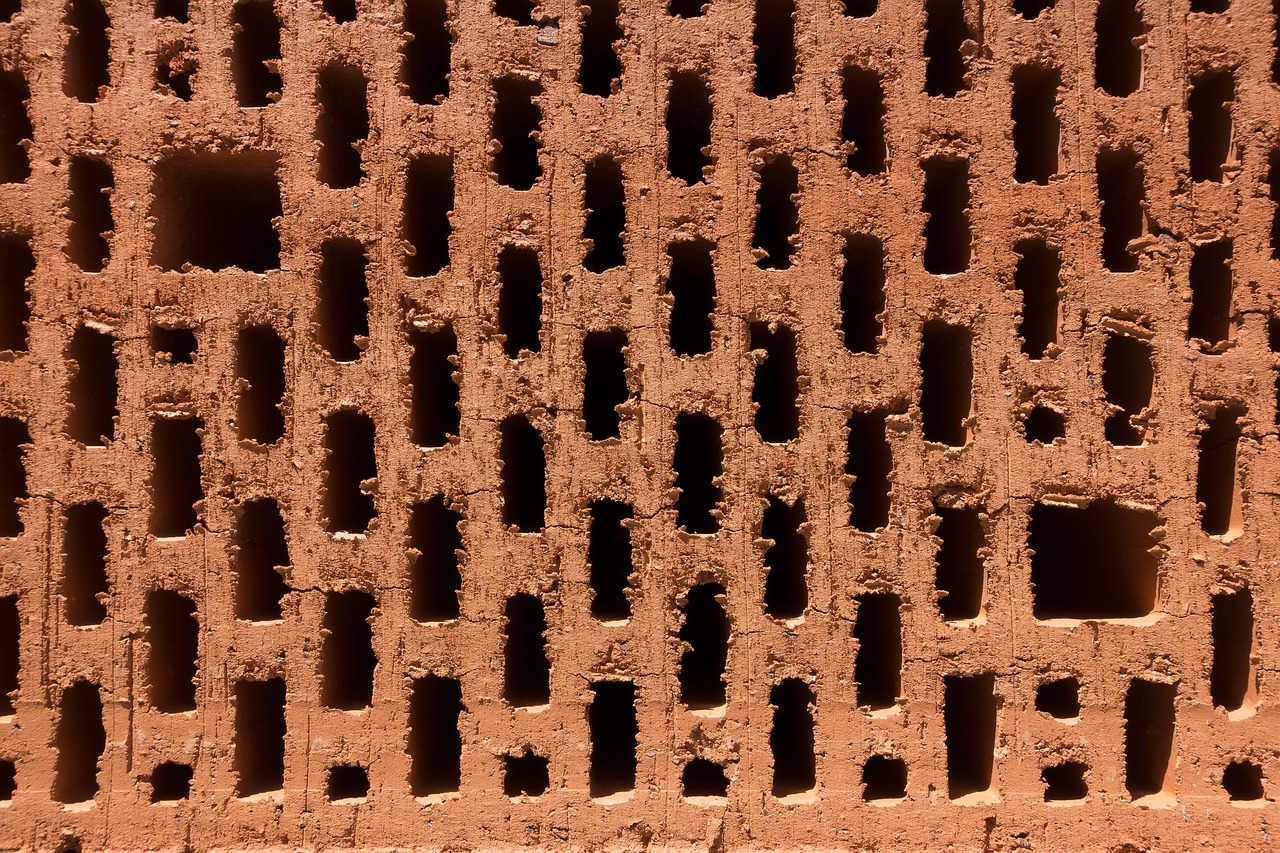

Our sustainable bricks consist mainly of laterite, a fully weathered and characteristically red earth. In the manufacturing process, they are pressed under pressure to form a shaped brick that is mechanically interlocked with adjacent bricks. In the building process, this makes it possible to dispense with the use of mortar between the stone layers (so-called dry masonry).

The laterite soil is a widespread surface product in West Africa, and is produced, for example, as a by-product of (open-pit) mining or can be extracted during earthworks or straightening on the property to be built on and processed into masonry blocks.

Due to the interlocking of our bricks, their flat dimensions and the fact that they do not require mortar, they can also be laid by people who have no specialist knowledge in the building sector. Training or instruction by a specialist on the construction site is sufficient.

Nowadays, a large part of the building materials is imported to Ghana.

This includes cement and cement clinker, which come to Ghana exclusively from imports, often from China.